Introduction  |

System  |

Products  |

Documentation  |

Price-List  |

Company  |

Contact  |

System

Air humidification by the method of direct deep purified water fogging

The manufactured air humidification systems are adiabatic. It means that water shouldn’t be heated for humidification. This makes it possible not only to achieve maximum efficiency in energy consumption, but also to minimize routine maintenance. Water is fogged by atomizing nozzles with orifice diameter of 85 µm (0.3 GPH), 2x85 µm (0.6 GPH) or 200 µm (0.9 GPH) under high pressure and creates fine fog, which instantly evaporates filling the air with moisture and does not accumulate on the floor, furniture, equipment and other items. These humidification systems can be used in residential and office areas. All the systems are equipped with the preliminary water purification and softening module (optionally). This ensures a long lasting central module's and fogging nozzles' operation, as well as purity of sprayed water, which is safe for health and does not create any scurf. Careful water pre-treatment can rid the system of contained minerals, microorganisms and algae growth.

Water treatment and pump units are usually located in suitable utility area, high pressure tubes and fogging nozzles are placed behind walls or ceilings and generally are invisible. One can set the desired humidity level in each room independently with the help of special regulators.

|

Today BuhlerAHS delivers 3 series of adiabatic air humidification systems: Playgreen is 2-zone, Manitoba is 10-zone, Superior is premium 10-zone. Their basic differences are capacity (fogged water - GPH) and number of humidification zones (simultaneously turned-on groups of nozzles). |

Basic technical advantages of the system:

- Basically water is demineralized by 97-99% (99.5% for Superior 18), i.e. practically distilled; it is possible due to multistage filtration: softener (optionally), mechanical microfilter, carbon filter, RO filter (2-stage for Superior 18).

- Additional deionization module supplies fully purified water of 0.1 µS/cm conductivity.

- Water is sterilized due to the built-in UV 2-stage decontaminator (continuous extensive UV sterilization for Superior 18).

- Each nozzle may serve from 100 to 1,500 sq ft according to the type.

Basic systems specifications

| System characteristics |

Playgreen 6 / Playgreen 12 |

Manitoba 12 | Superior 18 |

|---|---|---|---|

| Service area | Up to 3,000 sq ft / Up to 6,000 sq ft |

Up to 6,000 sq ft | Up to 9,000 sq ft |

| Rated capacity | Up to 1.6 GPH / Up to 3.2 GPH |

Up to 3.2 GPH |

Up to 4.8 GPH |

| Maximum number of independent zones |

2 | 10 (20 cascaded) |

10 (20 cascaded) |

| Maximum number of nozzles |

6 / 12 |

12 (24 with sub-zones) |

18 (36 with sub-zones) |

| Power consumption | Less than 200 W / Less than 230 W |

Less than 300 W | Less than 600 W |

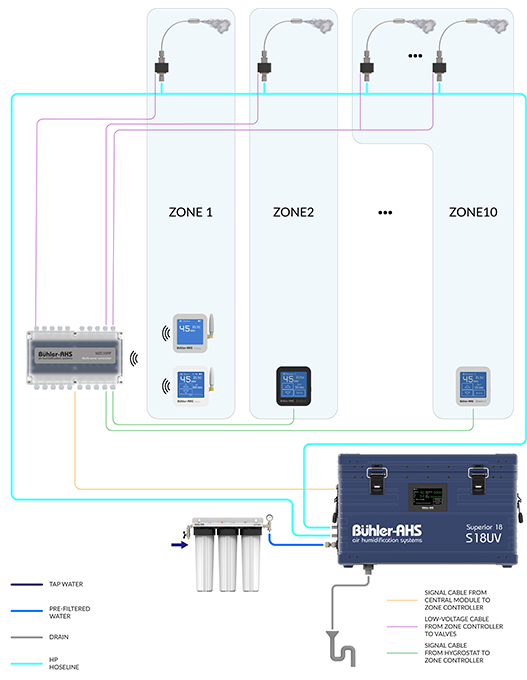

Superior 18 is Premium high capacity system with S18UV units (4.8 GPH)

with 2-stage reverse osmosis and SEPAMED pump

The central module's capacity is 4.8 GPH (18 LPH). The module supports up to 10 (20 cascaded) independent humidification zones. In addition to the central module, the ultra-carbon filter and the softener (optional) must be added. Superior 18 system provides the deepest possible water treatment thanks to 2-stage reverse osmosis and continuous extensive sterilization of water by ultraviolet light. Superior 18 system has high performance and may operate with a group of rooms with the total volume up to 90,000 ft3. Humidistats are installed in rooms and control nozzles maintaining in each separate zone its own humidity level.

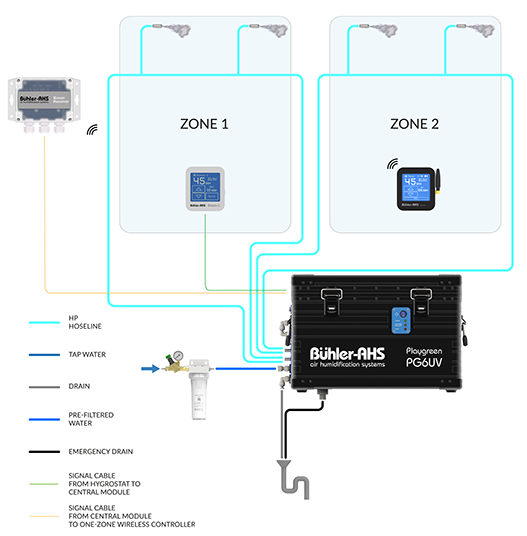

(DISCONTINUED) Playgreen 6 is 2-zone standard capacity system with PG6UV unit (1.6 GPH)

with the patented technology of double pass through the reverse osmosis membrane

The central module's capacity is 1.6 GPH (6 LPH). The system of valves is inside the unit and can maintain two independent humidification zones. The system is very compact and ideal for two groups of rooms with the total volume up to 30,000 ft3. The system with PG6UV is equipped with the 5 + 2 (optionally) stage filtration including continuous 2-stage UV water sterilization. Humidistats are installed in humidification zones and control nozzles.

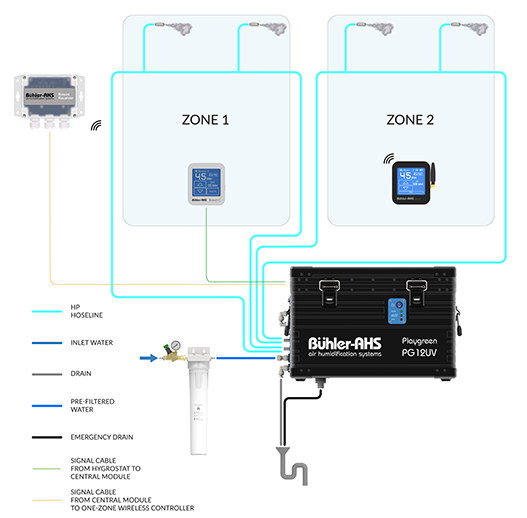

(DISCONTINUED) Playgreen 12 is 2-zone high capacity system with PG12UV unit (3.2 GPH)

with the patented technology of double pass through the reverse osmosis membrane

The central module's capacity is 3.2 GPH (12 LPH). The system of valves is inside the unit and can maintain two independent humidification zones. In addition to the high pressure unit, filter and softener (optional) units must be added, their parameters are chosen in accordance with the quality of supplied tap water. All water goes through inner 2-stage UV treatment. This system is very effective and can serve two groups of rooms with the total volume up to 60,000 ft3. Humidistats are installed in humidification zones and control nozzles.

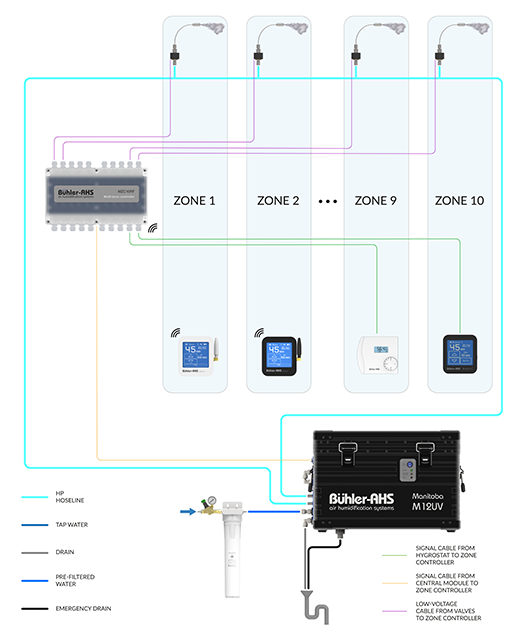

(DISCONTINUED) Manitoba 12 is 10-zone high capacity system with M12UV unit (3.2 GPH)

with the patented technology of double pass through the reverse osmosis membrane

The central module's capacity is 3.2 GPH (12 LPH). The module supports up to 10 (20 cascaded) independent humidification zones. In addition to the high pressure unit, filter and softener (optional) units must be added, their parameters are chosen in accordance with the quality of supplied tap water. All water goes through inner 2-stage UV treatment. This system is very effective and can serve a group of rooms with the total volume up to 60,000 ft3. Humidistats are installed in humidification zones and control nozzles, which create a unique relative humidity in each room.

All the equipment has a leakage protection system, malfunction and water shutdown sensors. In case of malfunction or breakdown all separate components of the system are easily disconnected for servicing. All modules are compact, completely self-contained and automated. Frequency of service depends on the quality and quantity of water used, usually it is carried out once a year (once in 2-3 years for Superior 18). All equipment is certified and tested to correspond to technical specifications after assembly.